Coriolis mass flowmeter measures high viscosity media

Coriolis mass flowmeter measure high-viscosity liquid media:

High-viscosity liquid media refers to liquids with higher viscosity such as crude oil, heavy oil, residual oil, palm oil (CPO), peanut butter, lime slurry, etc.

At present, in measuring the flow of high-viscosity liquids, Coriolis mass flowmeters have been used in many places, and good application results have been achieved.

Application practice shows that

Coriolis mass flow meters are suitable for working in high-viscosity liquid media.

And it has good reliability and high accuracy.

But in its use, there are also some problems that should be paid attention to.

If the viscosity of the medium is high, it is easy to stick to the wall of the measuring tube, forming a “wall hanging” phenomenon, which will affect the vibration frequency of the measuring tube and reduce the measurement accuracy.

When the process conditions are intermittent transportation, this problem should be paid more attention.

When palm oil or heavy oil is stopped as a medium with high viscosity,

It needs to be cleaned immediately, just a few minutes.

If you forget to clean it, it will take more time to clean it when you use it again.

have to be aware of is,

Make sure that the pipe is completely full of liquid.

If the pipe is not full, the measurement will be inaccurate.

For example, If palm oil contains air, it cannot be ensured that the pipe is full, Coriolis flowmeter needs to be installed perpendicular to the pipe, and the medium flows from bottom to top, so as to ensure that the palm oil CPO pipe is full during the measurement.

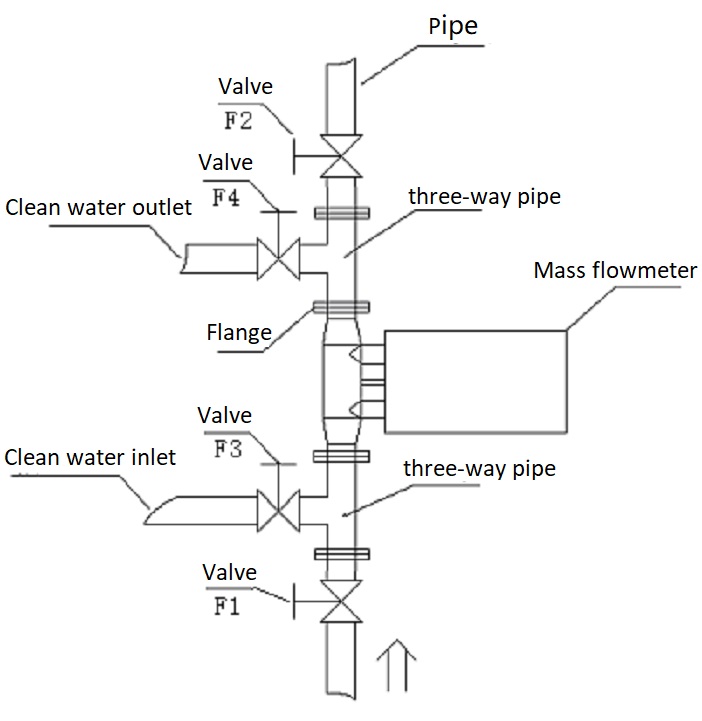

Here we provide a mass flow meter to measure heavy oil installation and automatic cleaning program:

1. Install automatic valves F1 and F2 on the upstream and downstream pipelines of the mass flowmeter, and clean the branch pipelines;

2. Install automatic valves F3 and F4 on the cleaning branch pipeline.

Way of working:

1. Normal working condition. Valves F1 and F2 are opened, and valves F3 and F4 are closed. The heavy oil pump is turned on, and the heavy oil enters the mass flow meter through valve F1 and flows out of valve F2. The mass flowmeter measures normally;

2. Pipeline cleaning status.

When the heavy oil pump stops, first close the valves F1 and F2, and then open the valves F3 and F4.

Start the hot water pump, and the cleaning hot water enters the mass flowmeter from the cleaning branch pipeline through the valve F3, and flows out from the valve F4 through the cleaning branch pipeline.

The mass flow meter is powered off to stop measurement.

Or the mass flow meter will record the total value before cleaning without powering on, and then reset the total value to zero after cleaning.

3. After cleaning, turn off the hot water pump and close the valves F3 and F4.

Valves F1 and F2 remain closed.

When working normally next time, first open the valves F1 and F2, and keep the valves F3 and F4 closed.

The heavy oil pump is turned on for normal operation.

This solution is suitable for various high-viscosity media: heavy oil, palm oil (CPO), crude oil, residual oil, peanut butter, lime slurry, etc.

The following is a schematic diagram of the program:

Send your inquiry, our engineer will provide the plan